Spanish Pavilion for Expo Shanghai 2010

After hosting the 2008 Olympic Games in Beijing in 2010, China is once again showcasing itself as an emerging country by successfully hosting a top notch World Expo for the first time ever in China. Universal expos are the ideal setting for countries to spotlight their best features and advertise themselves to the rest of the world.

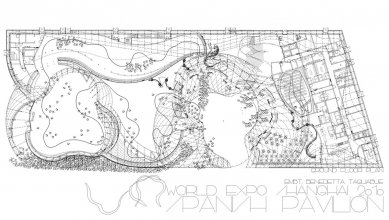

The Spanish Pavilion is located in the part of the expo grounds designated for national pavilions. Since the initial phases of the competition our intention has been to avoid conventional literal representations of the country in order to explore more abstract ideas. The pavilion is an expression of the climate of Spain and how it is experienced through architecture. With that in mind, we sought from the outset to revive an aspect of the extraordinary artistry of wickerwork, not just out of respect for tradition but in an attempt to reinvent wickerwork as a new construction technique appropriate for this project.

The Spanish Pavilion in Shanghai designed by EMBT explores the myriad possibilities offered by wicker weaving techniques. Wicker, furthermore, is a material that adds an ecological and sustainable factor to every part of the building.

The technique of basket making, the process of manually weaving plant fibres, is a global tradition shared by every culture throughout history. Despite the variations specific to geographical regions and plant varieties, nearly identical techniques are used in both the East and the West. In this way, choosing the material for the pavilion meant building a bridge between two cultures of the Spanish visitors and of the Chinese hosts.

The semi-transparent quality of the plant fibre textiles has been used to create courtyards that, like wicker baskets, create a wonderful atmosphere of light akin to the veiled transparencies of some Spanish-Islamic architectural elements — the just partly seen, seeing without being seen and the ever changing play of light and shadow — yet without falling into triteness. And the strong exterior light is diffused as it enters the interior through the overlapping space frames of wicker and steel.

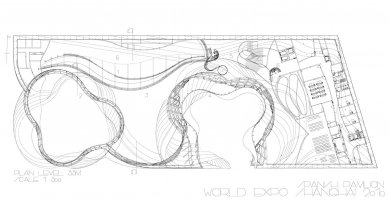

The largest courtyard in the pavilion opens up to the exterior to greet expo visitors and drawn them inside. The plaza could be considered to be to the city what the courtyard is to the house, a breathing space and a space to relax and enjoy yourself in. The other courtyards hover in an ambiguous territory between interior and exterior, in which visitors to the pavilion are in constant transit between one large courtyard-basket-plaza and the next; between spaces that are at once an inside and an outside. The pavilion thus eschews the model of the box containing a single space and expresses itself through a series of hybrid spaces that facilitate easy and fluid movement.

Structure:

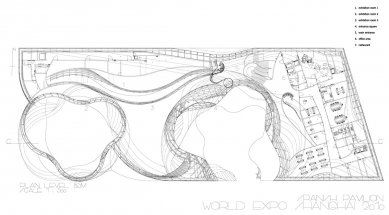

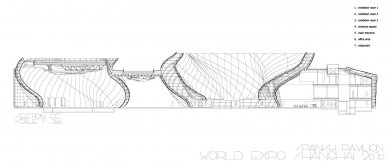

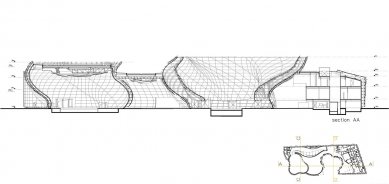

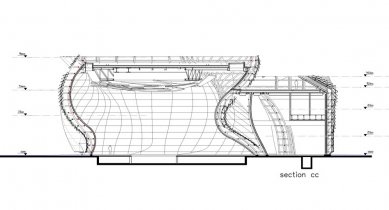

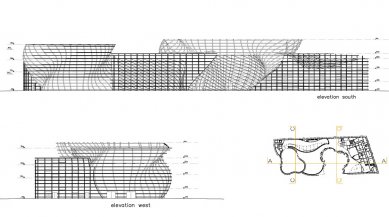

The nature of the project called for a new model of collaboration between the architectural team and the structural team. Moreover, an adequate structural system needed to be developed to support the project's freeform structure, characterised by highly complex curvature.

The exploration of the structural expression is best defined as a search for the "tensibility" of form, where a double curvature of the façade wrapping around the building simultaneously posed a challenge and provided the solution to the problem. The structure was resolved using a double space frame of tubular elements to form façades that can actively meet the requirements of different loads — their own weight, overloads, wind and seismic stress. The interior pillars, slabs, roofing and interior nuclei constitute a structural system in which every element is essential to adequately respond to actions as a whole.

The form of the building was manipulated using sophisticated computer-assisted design software and the surfaces were then sliced into vertical and horizontal planes producing curves that defined the axes of the tubular structure. By this process, the double curvature form was formalised into the combination of two families of tubing with simple curves, horizontal and vertical, which reduced the complexity of fabricating the elements in the workshop. One of the postproduction simplifications applied to the tubing was adapting the variable curve that was produced to a limited number of different curves. The complex three-dimensional models were also used as a system of communication between the architecture studio, the engineers and the manufacturers in the workshops.

Wicker:

In contrast to the advanced construction of the tubular metal structure, the wicker panels that cover the façade were made using much simpler, even ancestral, methods. The panels were built by local wicker artisans of the Shanghai region who work in small shops using a wicker weave stretched over slightly distorted rectangular tubular metal frames that give the panels their warp. An expressiveness rarely found in contemporary 21st-century buildings was achieved by using simple methods that differ very little from age-old traditional techniques. The spaces left open by the wicker allow for light to pass through into the interior, creating a beautiful play of light and shadow.

The Spanish Pavilion is located in the part of the expo grounds designated for national pavilions. Since the initial phases of the competition our intention has been to avoid conventional literal representations of the country in order to explore more abstract ideas. The pavilion is an expression of the climate of Spain and how it is experienced through architecture. With that in mind, we sought from the outset to revive an aspect of the extraordinary artistry of wickerwork, not just out of respect for tradition but in an attempt to reinvent wickerwork as a new construction technique appropriate for this project.

The Spanish Pavilion in Shanghai designed by EMBT explores the myriad possibilities offered by wicker weaving techniques. Wicker, furthermore, is a material that adds an ecological and sustainable factor to every part of the building.

The technique of basket making, the process of manually weaving plant fibres, is a global tradition shared by every culture throughout history. Despite the variations specific to geographical regions and plant varieties, nearly identical techniques are used in both the East and the West. In this way, choosing the material for the pavilion meant building a bridge between two cultures of the Spanish visitors and of the Chinese hosts.

The semi-transparent quality of the plant fibre textiles has been used to create courtyards that, like wicker baskets, create a wonderful atmosphere of light akin to the veiled transparencies of some Spanish-Islamic architectural elements — the just partly seen, seeing without being seen and the ever changing play of light and shadow — yet without falling into triteness. And the strong exterior light is diffused as it enters the interior through the overlapping space frames of wicker and steel.

The largest courtyard in the pavilion opens up to the exterior to greet expo visitors and drawn them inside. The plaza could be considered to be to the city what the courtyard is to the house, a breathing space and a space to relax and enjoy yourself in. The other courtyards hover in an ambiguous territory between interior and exterior, in which visitors to the pavilion are in constant transit between one large courtyard-basket-plaza and the next; between spaces that are at once an inside and an outside. The pavilion thus eschews the model of the box containing a single space and expresses itself through a series of hybrid spaces that facilitate easy and fluid movement.

Structure:

The nature of the project called for a new model of collaboration between the architectural team and the structural team. Moreover, an adequate structural system needed to be developed to support the project's freeform structure, characterised by highly complex curvature.

The exploration of the structural expression is best defined as a search for the "tensibility" of form, where a double curvature of the façade wrapping around the building simultaneously posed a challenge and provided the solution to the problem. The structure was resolved using a double space frame of tubular elements to form façades that can actively meet the requirements of different loads — their own weight, overloads, wind and seismic stress. The interior pillars, slabs, roofing and interior nuclei constitute a structural system in which every element is essential to adequately respond to actions as a whole.

The form of the building was manipulated using sophisticated computer-assisted design software and the surfaces were then sliced into vertical and horizontal planes producing curves that defined the axes of the tubular structure. By this process, the double curvature form was formalised into the combination of two families of tubing with simple curves, horizontal and vertical, which reduced the complexity of fabricating the elements in the workshop. One of the postproduction simplifications applied to the tubing was adapting the variable curve that was produced to a limited number of different curves. The complex three-dimensional models were also used as a system of communication between the architecture studio, the engineers and the manufacturers in the workshops.

Wicker:

In contrast to the advanced construction of the tubular metal structure, the wicker panels that cover the façade were made using much simpler, even ancestral, methods. The panels were built by local wicker artisans of the Shanghai region who work in small shops using a wicker weave stretched over slightly distorted rectangular tubular metal frames that give the panels their warp. An expressiveness rarely found in contemporary 21st-century buildings was achieved by using simple methods that differ very little from age-old traditional techniques. The spaces left open by the wicker allow for light to pass through into the interior, creating a beautiful play of light and shadow.

Courtesy of Miralles Tagliabue EMBT

0 comments

add comment